The Kanban Principle: Optimum production process control thanks to the Kanban system

Kanban principle - Good to know

The Kanban principle was originally developed by Taiichi Ohno at Toyota in Japan in 1947. It is a system based on the pull principle for controlling material flow and production. The goal is to ensure a seamless material supply for production. Traditional Kanban systems use two bins in a cycle and mostly Kanban cards as information carriers to control the production process. All details such as item number and description, filling quantity of the bin and supplier are put on this information carrier.

Kanban process at Würth - Delivery security for your small parts

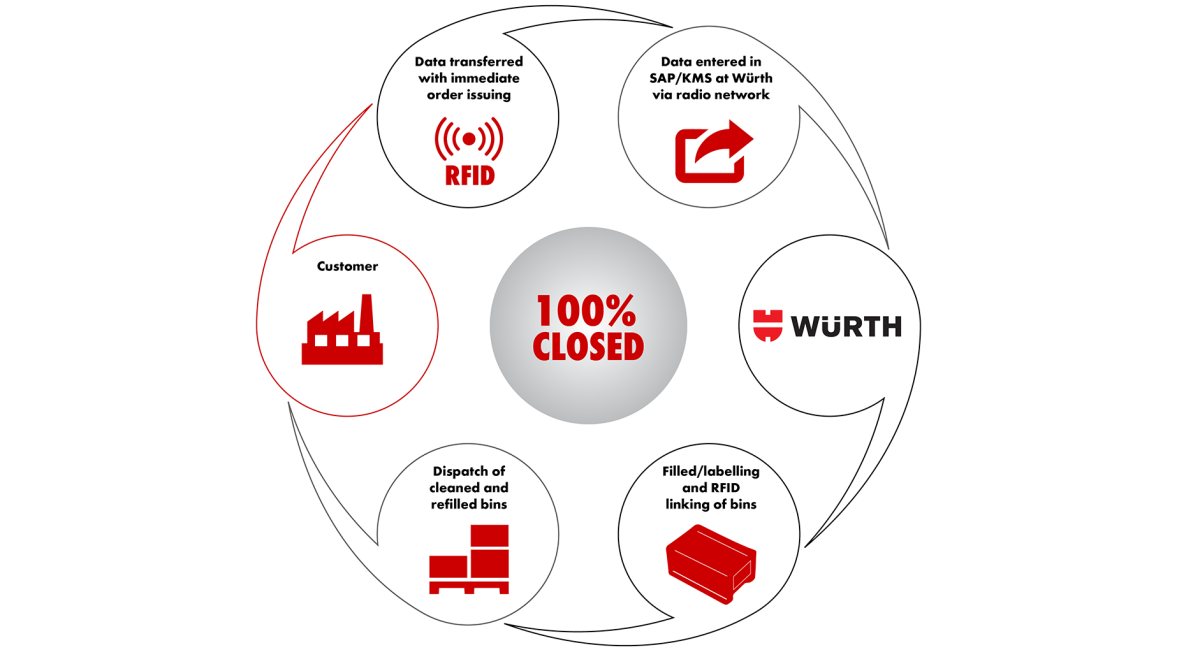

The material flow is managed in Kanban systems by Würth Industrie Service via two bins, our Würth small load carrier W-KLT®2.0. The information carriers used are a Kanban label in combination with various technologies for the automatic control of your production process. In the past, a hand scanner was used to trigger the demand, today more than half of our customers use standard RFID-based system solutions for automated reordering, and in the future optical, intelligent technologies such as iBin® modules can be used.

In the Kanban system of Würth Industrie Service you can manage your direct materials such as fasteners, fastening technology, DIN / standard parts as well as special and drawing parts as well as for your indirect needs in the field of MRO, operational and auxiliary materials.

Data management in Kanban processes

Each bin movement is captured and documented, so that we can give you information about the status of your Kanban system at any time. This is enabled by Kanban Management Software developed in-house and our specialised European Kanban logistics centre in Bad Mergentheim, as well as the barcoded labels, RFID tags or iBin® modules.

The data is used to schedule all C-Parts close to the point of use, to optimise stock levels and warehouse technology regularly and to update statistical data. As a customer, you can also find all of the data using the WIS Portal information platform.

At the same time, a variety of special parts, parts designed as per drawings and specific commodity groups may be handled effectively. Our employees plan your specific, cost-optimised solution in consultation with all departments. We implement the system in cooperation with your company, and provide further support for product standardisation of your C-Parts.

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.